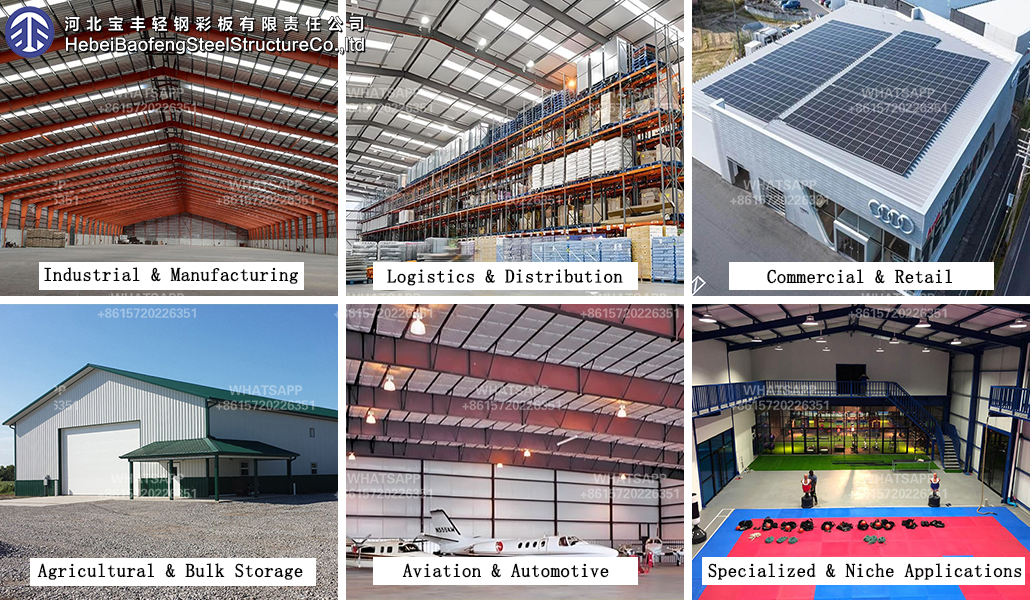

Steel warehouses are suitable for a wide range of applications

Steel warehouses are highly versatile and suitable for a wide range of applications due to their inherent strengths. Their adaptability stems from the clear-span design (no interior columns), ease of expansion, and customizable features.

Here’s a breakdown of their most common and suitable applications:

1. Industrial & Manufacturing

Factories & Assembly Plants: Provide large, unobstructed floorspace for production lines, heavy machinery, and inventory staging.

Workshops & Repair Bays: Ideal for automotive, machinery, or equipment repair with high ceilings for lifts and cranes.

Raw Material & Component Storage: Store bulk materials, palletized goods, and parts in a secure, organized environment.

2. Logistics & Distribution

Distribution Centers (DCs) & Fulfillment Centers: The backbone of e-commerce and supply chains. Designed for high-volume receiving, sorting, and shipping, often incorporating mezzanines and advanced racking systems.

Freight & Trucking Terminals: Serve as hubs for cross-docking, trailer loading/unloading, and temporary freight storage.

Cold Storage & Refrigerated Warehouses: Can be insulated and clad with special panels to create temperature-controlled environments for food, pharmaceuticals, and perishable goods.

3. Commercial & Retail

Big-Box Retail & Wholesale Clubs: (e.g., Home Depot, Costco). The building itself is often a large steel warehouse with a retail front.

Showrooms & Indoor Sales Lots: For vehicles, boats, RVs, or large equipment, combining storage and display.

Back-of-House Storage: Attached or separate storage for retail inventory.

4. Agricultural & Bulk Storage

Grain Silos & Feed Storage: Often use specific corrugated steel panels for silos and bunkers.

Equipment Storage: Shelter for tractors, combines, and other large farm machinery from the elements.

Processing & Packing Facilities: For sorting, packaging, and storing produce or other agricultural products.

5. Aviation & Automotive

Aircraft Hangars: Require very wide clear-spans and high doors. Steel is the default material for hangars.

Dealership Storage & Service Centers: For vehicle inventory and service bays.

Bus & Fleet Vehicle Storage.

6. Specialized & Niche Applications

Sports & Recreation: Indoor soccer facilities, tennis centers, riding arenas, and recreational vehicle storage.

Municipal & Utility: Salt sheds for road maintenance, fire stations, vehicle and equipment storage for municipalities, and utility company depots.

Self-Storage Facilities: Easily subdivided into secure, individual units.

Data Centers: Increasingly popular due to the need for vast, column-free spaces for server racks, with reinforced floors for heavy loads.

Key Advantages Making Steel Warehouses Suitable for These Uses:

Cost-Effectiveness: Lower initial cost per square foot and faster construction time (quick ROI).

Durability & Low Maintenance: Resistant to pests, rot, and (with proper coatings) corrosion. Requires minimal upkeep.

Design Flexibility: Easily customized for door placements (overhead, dock-high), ceiling height, lighting, insulation, and interior layout.

Scalability: Can be expanded in length or width relatively easily to accommodate business growth.

Strength & Safety: Can support heavy mezzanines, crane systems, and roof-mounted equipment like HVAC or solar panels.

Conclusion

The steel warehouse is not a one-size-fits-all solution, but a highly adaptable building system. Its core benefits of strength, span, speed, and scalability make it the dominant and most suitable choice for virtually any application that requires a large, secure, and functional enclosed space for storage, commerce, or industry.

Categorías

último blog

Etiquetas

© Derechos de autor: 2026 Hebei Baofeng Steel Structure CO.,LTD Reservados todos los derechos.

IPv6 red apoyada